Address:

15/15A, Govindam Vihar, Macheda Mod, Nindar Road, Jaipur, Rajasthan 302013

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Material parting is a fundamental operation in manufacturing and machining processes, essential for separating workpieces from raw material stock or from larger components.

Key Considerations

Techniques for Material Parting

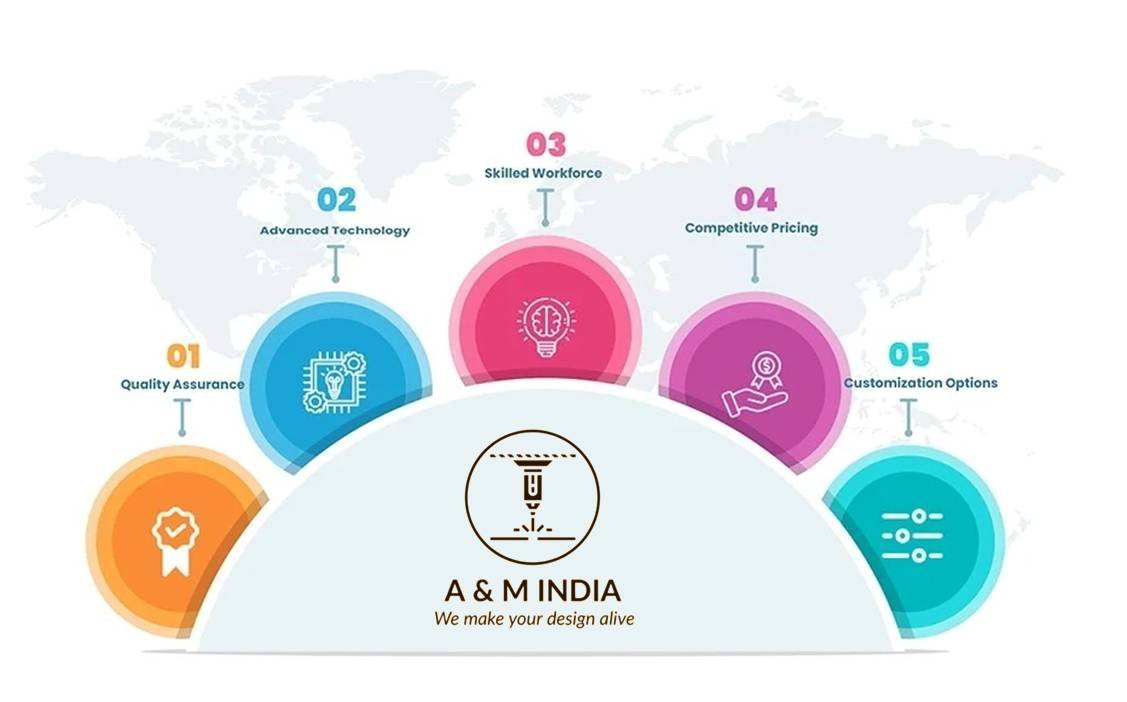

Quality is the cornerstone of everything we do. Our rigorous quality assurance processes ensure that every component we produce meets the highest standards of precision and reliability. From the initial design phase to the final inspection, we employ strict quality control measures to guarantee the excellence of our products.

Embracing the latest advancements in CNC machining technology ,

A & M India is equipped with state-of-the-art multi CNC machines. This advanced technology allows us to achieve unparalleled precision and efficiency in producing complex components.

Our team of highly skilled engineers and technicians is the backbone of our success. With years of experience and a deep understanding of CNC machining, our workforce is dedicated to delivering exceptional results on every project.

We understand the importance of cost-efficiency without compromising quality. Our competitive pricing structure ensures that you receive high-quality components at a fair and reasonable cost.

Every project is unique, and we pride ourselves on offering customized machining solutions tailored to your specific needs. From prototyping to full-scale production, we work closely with you to deliver components that match your exact specifications.