Address:

15/15A, Govindam Vihar, Macheda Mod, Nindar Road, Jaipur, Rajasthan 302013

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

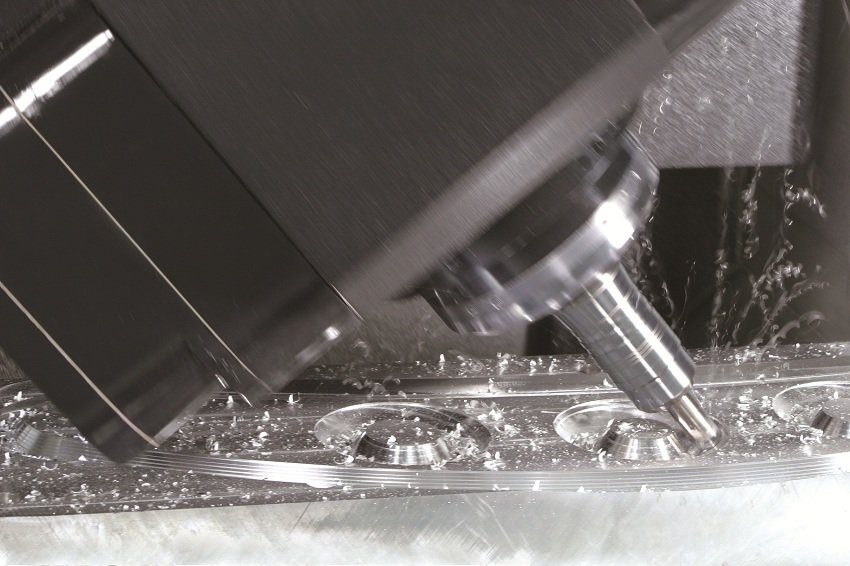

A & M India Machining not only makes quality parts, we help make quality products. Our CNC methodology follows the standards required for maximum efficiency and accuracy of every part produced.

Multi-axis CNC Turning And Milling Services Are Crucial For Industries That Require High Precision, Efficiency, And The Ability To Produce Complex Parts. These Services Are Widely Used In Automobile, Mining, Agriculture, Machinery, Energy And Industrial Manufacturing, Providing Significant Advantages In Terms Of Accuracy, Speed, And Cost Efficiency.

Learn More

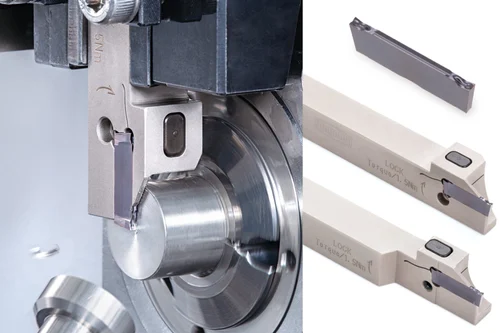

Swiss CNC Machining Is A Specialized Form Of Precision Machining That Involves The Use Of Swiss-type Lathes Or Swiss Screw Machines. These Machines Are Particularly Well-suited For Producing Small, Intricate, And High-precision Parts.

Learn More

MIG (Metal Inert Gas) And TIG (Tungsten Inert Gas) Welding Are Two Widely Used Methods In Metal Fabrication. Both Techniques Are Essential For Creating Strong, Durable Welds And Are Used In Various Industries, Including Automobile, Mining, Agriculture, Machinery, Energy, And Manufacturing.

Learn More

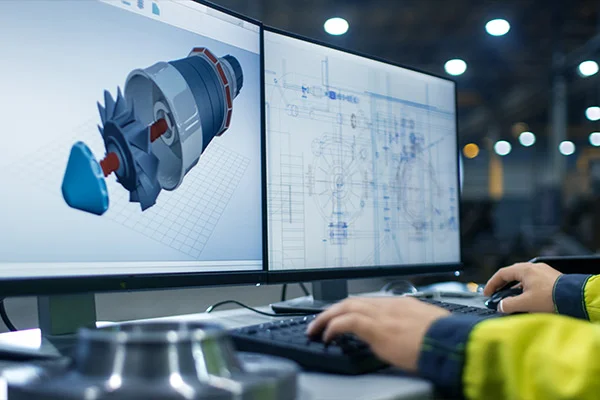

CAD (Computer-Aided Design) Designing And Development Is A Crucial Aspect Of Modern Engineering And Manufacturing Processes. It Involves The Use Of Computer Software To Create, Modify, Analyze, And Optimize Designs.

Learn More

Case Induction Hardening Is A Heat Treatment Process Use To Increase The Hardness And Wear Resistance Of The Surface Layer Of A Metal Component While Maintaining A Tougher And More Ductile Core. This Process Is Widely Use In The Manufacturing Industry, Especially For Parts That Require A Hard Exterior To Resist Wear And Fatigue While Retaining A Tough Interior To Absorb Impacts.

Learn More

Hardness Testing Is A Method Use To Determine The Hardness Of A Material, Which Is A Measure Of Its Resistance To Deformation. Our Sercices Is Essential For Understanding The Wear Resistance, Strength, And Ductility Of Materials, Making Hardness Testing A Critical Process In Materials Science And Engineering.

Learn More

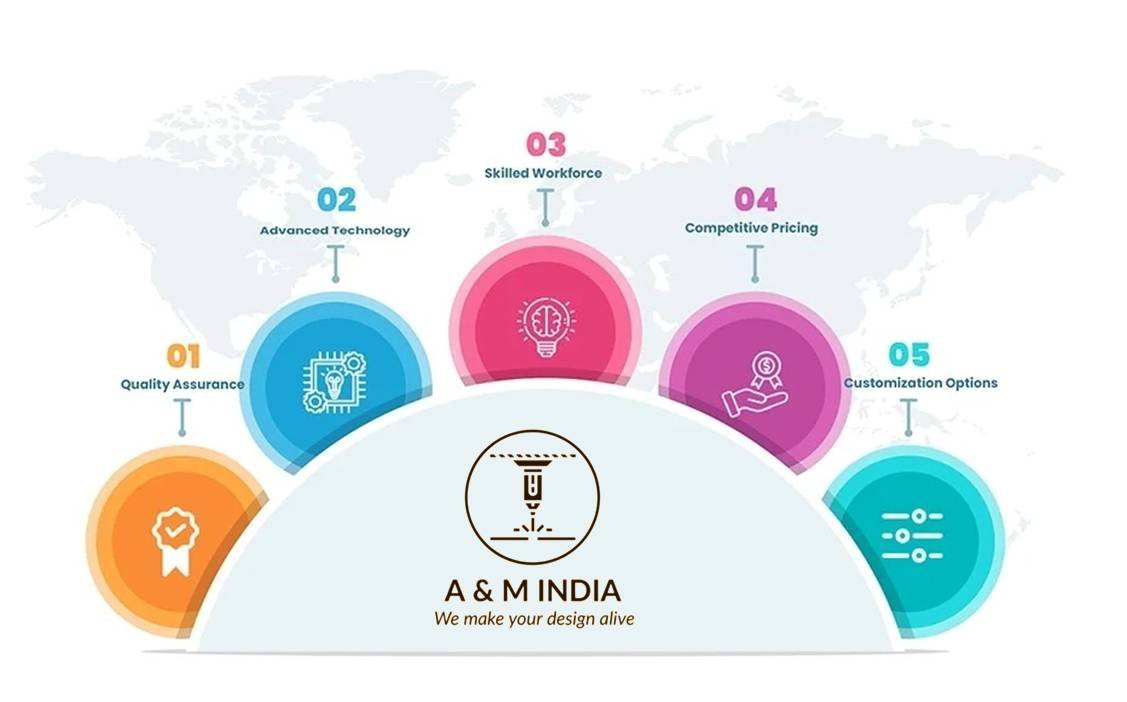

Quality is the cornerstone of everything we do. Our rigorous quality assurance processes ensure that every component we produce meets the highest standards of precision and reliability. From the initial design phase to the final inspection, we employ strict quality control measures to guarantee the excellence of our products.

Embracing the latest advancements in CNC machining technology ,

A & M India is equipped with state-of-the-art multi CNC machines. This advanced technology allows us to achieve unparalleled precision and efficiency in producing complex components.

Our team of highly skilled engineers and technicians is the backbone of our success. With years of experience and a deep understanding of CNC machining, our workforce is dedicated to delivering exceptional results on every project.

We understand the importance of cost-efficiency without compromising quality. Our competitive pricing structure ensures that you receive high-quality components at a fair and reasonable cost.

Every project is unique, and we pride ourselves on offering customized machining solutions tailored to your specific needs. From prototyping to full-scale production, we work closely with you to deliver components that match your exact specifications.