Address:

15/15A, Govindam Vihar, Macheda Mod, Nindar Road, Jaipur, Rajasthan 302013

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), involves using a continuous solid wire electrode that is fed through a welding gun and into the weld pool. An inert or semi-inert gas (usually argon or a mixture of argon and CO2) shields the weld from contamination.

TIG Welding

TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to produce the weld. An inert gas (usually argon) shields the weld area from contamination. A filler metal may or may not be used.

MIG and TIG welding are both essential techniques in metal fabrication, each with its own strengths and applications. MIG welding is favored for its speed, ease of use, and efficiency, making it ideal for high-production environments and larger projects. TIG welding, on the other hand, is preferred for its precision, quality, and versatility, making it suitable for intricate and detailed work.

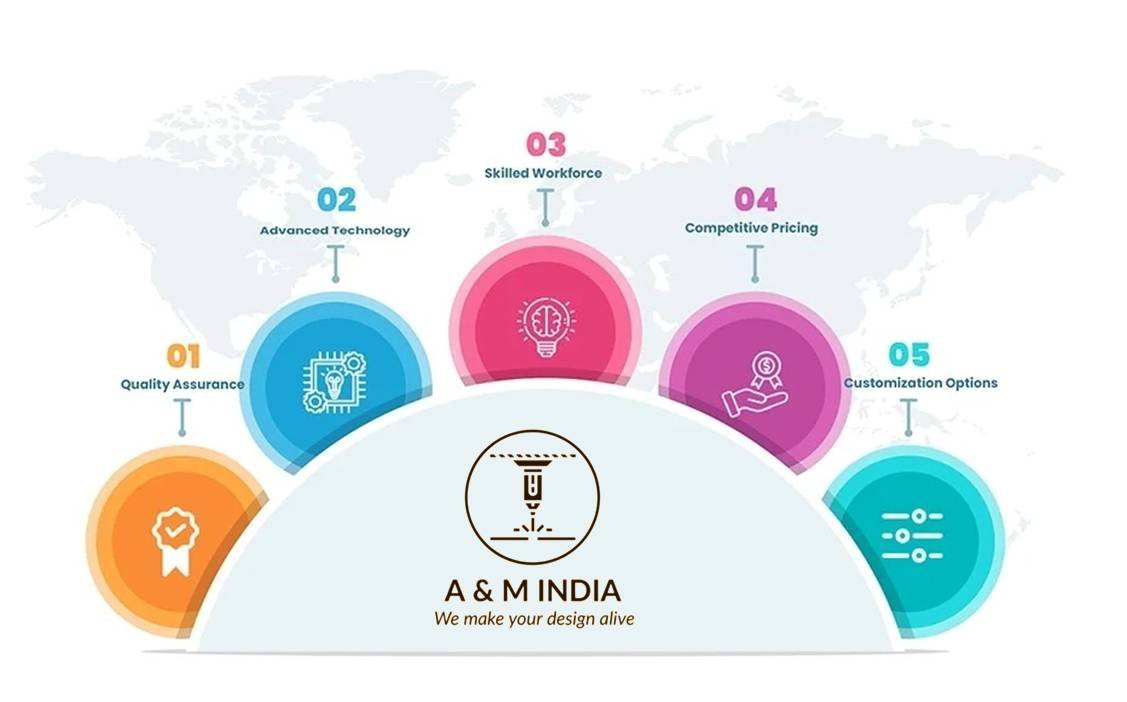

Quality is the cornerstone of everything we do. Our rigorous quality assurance processes ensure that every component we produce meets the highest standards of precision and reliability. From the initial design phase to the final inspection, we employ strict quality control measures to guarantee the excellence of our products.

Embracing the latest advancements in CNC machining technology ,

A & M India is equipped with state-of-the-art multi CNC machines. This advanced technology allows us to achieve unparalleled precision and efficiency in producing complex components.

Our team of highly skilled engineers and technicians is the backbone of our success. With years of experience and a deep understanding of CNC machining, our workforce is dedicated to delivering exceptional results on every project.

We understand the importance of cost-efficiency without compromising quality. Our competitive pricing structure ensures that you receive high-quality components at a fair and reasonable cost.

Every project is unique, and we pride ourselves on offering customized machining solutions tailored to your specific needs. From prototyping to full-scale production, we work closely with you to deliver components that match your exact specifications.